Our products

Reducing environmental impact throughout product lifecycle

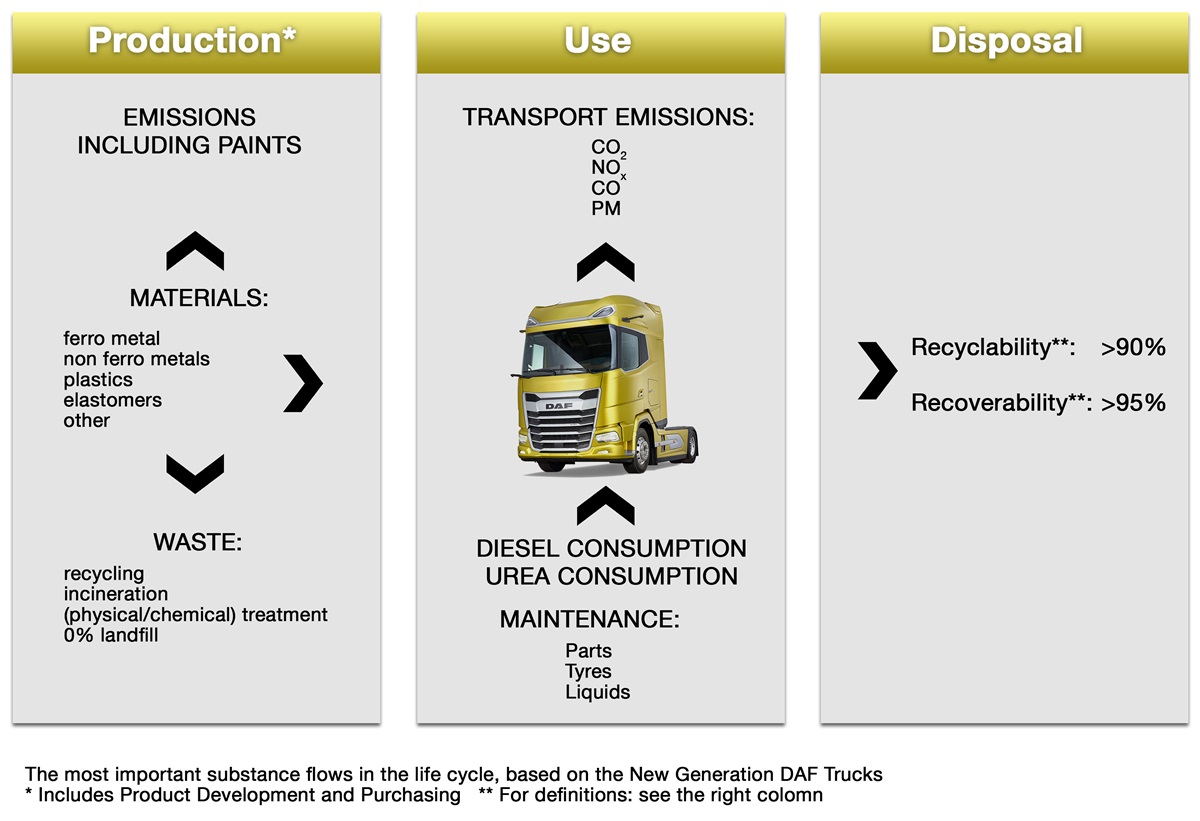

To help protect the environment, DAF takes into account the complete life cycle of a product, which consists of three stages: production, use and disposal.

The impact on the environment is greatest during operation of the truck; mainly as a result of fuel consumption and the associated emissions of harmful substances. During the production and disposal phases, the impact on the environment is considerably less. This is why DAF is focusing mainly on the truck operational phase to reduce the environmental impact.

**Definitions: see ISO 22628 "Road Vehicles - Recyclability and recoverability - Calculation Method" and Directive 2000/53/EG on end-of life vehicles

Recyclability: Ability of component parts, materials or both that can be diverted from an end-of-life stream to be recycled.

Recycling: Reprocessing in a production process of the waste materials for the original purpose or for other purposes, excluding processing as a means of generating energy.

Recoverability: Ability of component parts, materials or both that can be diverted from an end-of-life stream to be recovered.

Recovery: Reprocessing in a production process of the waste materials for the original purpose or for other purposes, together with processing as a means of generating energy.

Recyclability: Ability of component parts, materials or both that can be diverted from an end-of-life stream to be recycled.

Recycling: Reprocessing in a production process of the waste materials for the original purpose or for other purposes, excluding processing as a means of generating energy.

Recoverability: Ability of component parts, materials or both that can be diverted from an end-of-life stream to be recovered.

Recovery: Reprocessing in a production process of the waste materials for the original purpose or for other purposes, together with processing as a means of generating energy.

Learn more about the three phases to the life cycle: production (including product development and purchasing), use and disposal.

Thanks to our initiatives in these areas we have scored some impressive environmental achievements.